RESIN INFUSION

A great leap for boat manufacturing in South Africa

By Rob Naysmith

(Originally published in the September 2024 issue of SKI-BOAT magazine)

I AM one of those fortunate boaters who has lived through much of the evolution of ski-boats in South Africa. Not only the evolution in terms of design, which included that of the “radical” catamaran and tri-hulls, as on-the-water experience was gained, but also the evolution of manufacturing methods which included the introduction of resins, epoxies and fibreglass.

Our early ski-boats were wooden craft, most built by craftsmen following plans, both local and from across the seas, with a few slight modifications to suit local conditions. Many kit boats found their way to our shores to become the forerunners of some of the most popular boats around today.

Each of these boats took many months to build, including selecting the best timber, measuring and re-measuring, sawing, chiselling, drilling and using the best glues possible, with copper nails and brass screws, all affixed by hand.

The eye of the boat builder was most crucial, as was his knowledge of carpentry, the properties of each wood type and knowledge of how each boat would react on the water.

There was no second chance.

Then came the constant maintenance – scraping down, repainting, making sure the hull remained water-tight.

Back in the day there were no buoyancy requirements other than having sealed bulkhead compartments.

Next the array of synthetic products arrived which changed the face of boat building almost overnight. Glass fibres soaked in resin produced a boat building material that could be moulded into any shape or form, with a durability way exceeding that of timber.

Now boats could be reproduced as an exact copy of a proven hull, time and again. Production materials were now freely available and the production time of a new boat became a fraction of what it was, driving down costs substantially. We had arrived in the era of ski-boat mass production.

Without getting into too many of the technicalities of synthetic materials, in boat building we use three basic products: fibreglass, resin, and gelcoat. On their own each one is fairly useless for this application, but once combined, they become an almost indestructible medium.

Resin relies on the fibreglass for strength, fibreglass relies on the resin for its shape and rigidity, and the resin and fibreglass mixture relies on the gelcoat to protect it. It’s way more complicated and calculated than that, but the principle remains the same.

Years back we measured the strength of a hull by how solid, thick and heavy it was, because that indicated lots of resin and glassfibre had been used. We were happy with that.

Then a few clever people sat down and did some calculations on the materials, knowing that resin is hard, brittle, has little inherent strength, cracks easily under pressure and yet constitutes the bulk of the weight.

The secret lay in giving the fibreglass just enough resin for it to meet design standards. The concept of infusing the resin into the fibreglass under a vacuum environment was born.

GYPSKI BOATS FOR SPORTFISHERS

Earlier in 2024 I was approached to build a Gypski that could be housed on the front of a charter sportfishing vessel, to be used as both a tender and a fishing ski-boat. As the Gypski would need to be raised and lowered to the water by an on-board crane, the total weight was a major factor. The weight of the twin 20hp outboards was non-negotiable, so the reduction in overall weight had to come from the boat itself.

Earlier in 2024 I was approached to build a Gypski that could be housed on the front of a charter sportfishing vessel, to be used as both a tender and a fishing ski-boat. As the Gypski would need to be raised and lowered to the water by an on-board crane, the total weight was a major factor. The weight of the twin 20hp outboards was non-negotiable, so the reduction in overall weight had to come from the boat itself.

The only way to meet these demands was to step into the 21st century. Well, more like take a moon jump.

I knew of the resin infusion concept, had read many articles on the process, and salivated over a few boats built using this method. I also knew the guru, one of the pioneers, Chris Scarrott of Aerontec – suppliers of the latest and most advanced boat building products in South Africa.

Chris jumped at the opportunity with a passion I’ve only ever seen in a fisherman during the shad run. He popped over to our factory at Down South Marine, looked at the moulds we would use for the boat, and drew up a list of materials required for our project. He explained the advantages of the resin infusion method with such enthusiasm that I was sold before he had finished explaining the process.

Our first task was to modify our moulds to accommodate the vacuum process. That was probably the most difficult part of the project. After a week or two we had completed our mould modifications to Chris’s standards, then came the polishing, waxing, polishing and waxing … for days.

Finally, the big day came and the colour-matched gelcoat was sprayed into the hull mould. I used this opportunity to try out a new gelcoat strengthening additive along the keel area in place of a stainless steel keel strip.

While allowing the gelcoat time to cure, we cut the different fibreglass laminates into the required panels, using the same material lay-up as in all previous Gypski boats. Then, one by one, each laminate was laid down in order and snugged into place.

These laminates were then covered with Green Aeroflow mesh, a specially designed resin distribution material plastic mat which allows the resin to flow freely through the fabric in the mould. We also laid the resin feed tape to direct the incoming resin in a predetermined direction.

This was followed by the carefully calculated placement of infusion connectors which determine the points at which resin will enter the mould, be drawn along the feed tapes, under the Aeroflow mesh mat and infused into the fibreglass.

Then came the vacuum bag which was sealed air-tight around the rim of the mould, along with vacuum tubes through which the vacuum is applied.

The resin feed tubes were then connected to the infusion connectors and each line clamped to adjust the flow.

The last test before the resin was released was to check the vacuum integrity, which must hold a stable maximum vacuum pressure of 1 bar at around 90% for at least the calculated time from the start of the infusion to the gelation of the resin; in this case 60 minutes.

With the calculations complete for various gel times and flow rates for each resin batch, the flow pipes were opened.

As the process began and the first batch of resin entered the mould, it felt like we were conducting an orchestra – holding flow on one area, increasing flow on another, bringing in the next resin batch before the first was exhausted, and all the while making sure that the entire project was fully injected before the first resin mix began to cure.

Basically, the resin enters along the keel area and works its way along the hull to the chines. The keel flow is then halted and the chine flow is opened for the resin to flow up the sides towards the vacuum tubes.

Our calculation on injection time before the cure started was 40 minutes, with a further 60 minutes for complete cure before vacuum release. So, there it was – we had just produced a complete hull in only a few hours as opposed to days with the hand-lay process.

The following morning, we removed all the infusion consumables, mesh materials, mats mesh, tubes, taps, cover, recyclable pipes, vacuum bag and seals etc. The time had come to feast our eyes on our first attempt at leaping into the future.

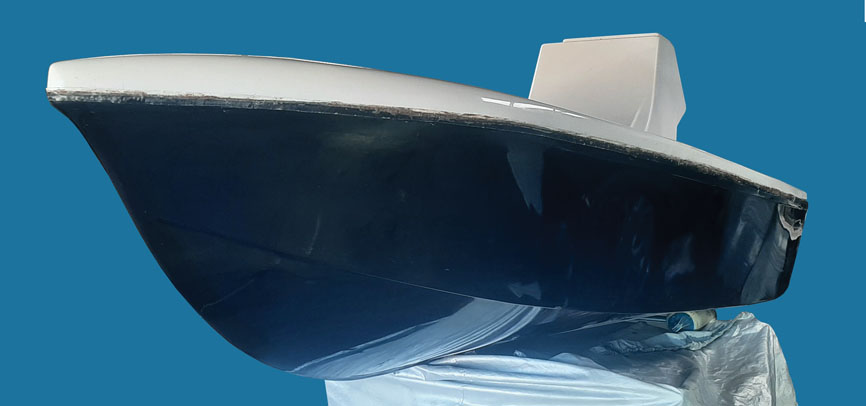

The result was way beyond what I’d expected. The internal finish was excellent – no fibreglass burn patterns, no resin unevenness, no air bubbles, just absolutely beautiful. As she majestically rose out of the mould, the quality was undeniable. The boat had a stunning finish and vastly superior strength compared to a hand-laid product.

But the big test was still to come: Had we achieved the necessary weight reduction?

A hand-laid Gypski hull weighs in at around 76kg; our new resin infusion method of Gypski production resulted in a hull weighing an incredible 31.3kg! Not only an impressive weight reduction, but also a three-fold increase in structural strength.

At the time of writing, we were nearing completion after just two weeks, and I cannot wait to find out her new total weight. Suffice it to say that we have far exceeded our production goals.

However advanced the process and result, there are still some points of caution to take note of.

With a lifetime of boating experience behind me, one aspect I’ve learned is that a boat must have a suitable weight to perform comfortably. Many times while navigating stormy seas on the long run back from the Cape tuna grounds, I have filled my fish-box with water to add weight for a more controllable ride.

Vacuum infusion produces a super-light boat which is perfect for calm seas and carrying heavy weights, but it will be tossed around in bad weather if it doesn’t have a load.

My overall impression of the vacuum resin infusion technique is one of amazement. We were able to produce a superior product that was lighter and stronger than previous Gypskis with a beautiful internal finish, all with a massive saving in production time.

We will still have a few modifications to make once she’s tested on the water, but she will definitely be super easy to handle, very fast and ultra-light on fuel.